Advantages of Interactive Guiding Operation Interface for Machines

In modern manufacturing, the precision and efficiency of machine operations are increasingly emphasized. With the rapid development of automation technology, reducing operator error rates and improving production line efficiency have become key concerns for companies. Against this backdrop, Interactive Guiding Operation has emerged as a solution. By installing light signals on machines, operators can perform tasks quickly and accurately, reducing error rates and increasing production efficiency. This technology not only simplifies the operational process but also shortens the training time for new operators, adapting to the demands of a changing market. It has become an essential tool for modern factories to enhance competitiveness and achieve smart manufacturing.

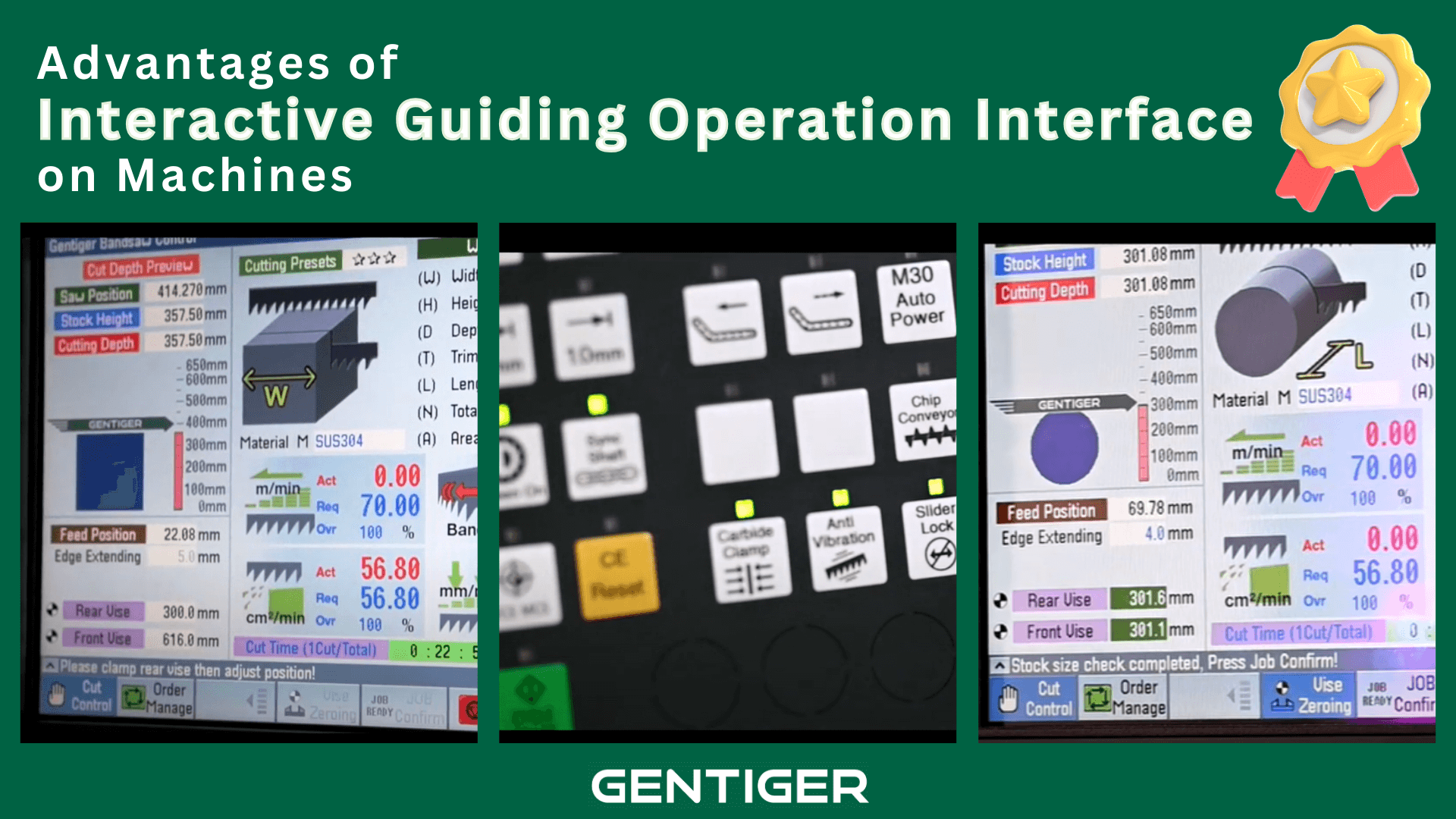

Interactive Guiding Operation is a technology that combines visual cues with machine operations, using intuitive light signals to guide operators in performing each step accurately. The principle involves using LED lights or other light sources on the machine to indicate the order of operations, steps, and precautions. When operators need to perform a task, the lights illuminate in sequence according to a preset process, guiding the next action and significantly reducing operational complexity and error rates.

With the assistance of interactive guiding, operators can easily manage even complex machine operations. This not only improves production efficiency but also enhances operational reliability. Particularly in industries with high precision requirements, interactive guiding technology has become a key tool for improving work quality.

Interactive Guiding Operation offers significant advantages in modern manufacturing, especially in improving production efficiency, enhancing safety, and shortening learning time.

-

Advantage 1: Enhanced Operational Efficiency

Light signals allow operators to quickly identify the next step, reducing operational time and significantly decreasing the likelihood of errors, resulting in a smoother production process. -

Advantage 2: Improved Safety

For high-risk operations, light signals provide clear warnings, alerting operators to potential hazards. These real-time visual cues can greatly reduce operational errors, ensuring the safety of both personnel and equipment. -

Advantage 3: Shortened Learning Time

Traditional machine operation training often requires extended periods to understand and memorize steps. However, interactive guiding enables new operators to quickly grasp the essentials and get up to speed. This reduces training costs, improves new operator efficiency, and shortens the transition from training to full operation.

The Interactive Guiding Operation technology plays a crucial role in modern manufacturing by providing visual guidance that significantly enhances production efficiency, strengthens operational safety, and shortens learning times. This technology enables operators to complete tasks quickly and accurately, reducing error rates and optimizing the overall production process. It is especially valuable in high-precision environments. As manufacturing continues to advance toward smart automation, the application prospects for Interactive Guiding Operation are increasingly broad. Companies that leverage this technology can not only improve production efficiency but also gain a competitive advantage in the market.

Further more, the Gentiger CNC High-Speed Horizontal Band Saw Machine series 's unique Dynamic Guiding Operate Interface (DGOI) is also a well-designed interactive guiding operation interface. If you would like to learn more, please feel free to contact Gentiger's team at TEL: 886-4-26836919 or E-mail: GT@gentiger.com.tw. We are here to provide you with more information and solutions regarding the CNC High-Speed Horizontal Band Saw Machine.